Frequently Asked Questions About Medical Cleanroom Filtration

The medical cleanroom filtration system is responsible for removing particles from the air thoroughly and consistently. From toxic substances to large particles that interfere with tests and research, restricting and controlling air quality through proper filtration is essential to protect both your work and your workers. When it comes to designing and implementing an effective and efficient cleanroom filtration system, it can be complicated to know what your medical cleanroom needs to be successful — from what types of filters you’ll use to how to design the ideal filtration system for your application. Read on for the answers to these frequently asked questions and more.

What Are the Different Types of Cleanroom Filters?

There are three main types of filters employed in cleanroom filtration systems: HEPA filters, ULPA filters, and pre-filters.

- HEPA Filters: High Efficiency Particulate Air filters remove particles 0.3µm or larger. They are the most commonly used filters in medical cleanrooms.

- Pre-Filters: remove the largest particles from the air, extending the life of the more valuable HEPA and ULPA filters.

- ULPA Filters: Ultra Low Particulate Air filters are even more powerful and expensive than HEPA filters, removing virtually all particles 0.12µm or larger.

Medical cleanrooms with highly sensitive processes may require more powerful cleanroom filtration in order to reach strict cleanroom classification standards.

How Many Filters Does My Medical Cleanroom Need?

The number of filters your medical cleanroom needs will depend on your cleanroom classification. Each ISO Class defines the maximum allowed particles, air change velocity, and percentage of ceiling coverage dedicated to filter/fan units. The number of filters you need will be what allows you to easily reach your stringent standards during cleanroom operation. In general, the “cleaner” your cleanroom has to be, the more filters you’ll need to achieve quality standards. However, filters alone won’t help you reach your classification requirements — the way you use them also matters. Employing an efficient airflow pattern will help your filters clean the air more efficiently. It can also extend the lifespan of your expensive HEPA filters by reducing the strain on just a few filters by evening out the filtering power across your cleanroom.

How Often Do Cleanroom Filters Need to Be Replaced?

Your specific filter replacement schedule may vary across your cleanroom, as one location may be dirtier than another — but having a clear schedule is essential for maintaining your medical cleanroom. Filter replacement every 3-5 years is common, but critical applications may find they need to replace filters every 1-2 years to ensure safety and quality. In addition to facility use, the type of filter in your cleanroom will affect the filter replacement schedule. Pre-filters, which form the frontline defense against particles in the cleanroom, need to be replaced much more frequently than the more expensive HEPA filters they protect.

HEPA Filter Replacement

While HEPA filters can last up to 10-12 years depending on the volume and air quality of the room, pre-filters are typically replaced biannually and inspected at least quarterly. Although HEPA filters are longer-lasting, there are many reasons you might need to replace them sooner, including:

- Evidence of filter plugging, such as a notable drop in pressure

- Leak-test failure

- Buildup of radiation

- Damage from handling or installation

- Media rupture

- Filter-frame or seal failure

Although valuable HEPA filters are not cheap to replace, it’s more cost effective to replace them too early than to pay for the extra power usage or damage to the facility should a faulty or loaded filter be left unaddressed.

Are My Medical Cleanroom Filters Working Effectively?

Your medical cleanroom filtration system should be inspected regularly — at least 4 times per year — to ensure it is effectively cleaning and changing the air in your cleanroom. Per ISO 14644-2, all cleanrooms must perform quality checks annually to check that the particle count allowances are met. If your medical cleanroom is ISO Class 5 or lower, these quality checks need to happen every 6 months. To test your cleanroom classification yourself, you can use a handheld particle counting device to measure particle size and number at varying zones in your cleanroom, then average the totals. If your findings exceed the allowed maximum count, your cleanroom filtration system likely needs an upgrade.

How Do I Design an Efficient Cleanroom Filtration System?

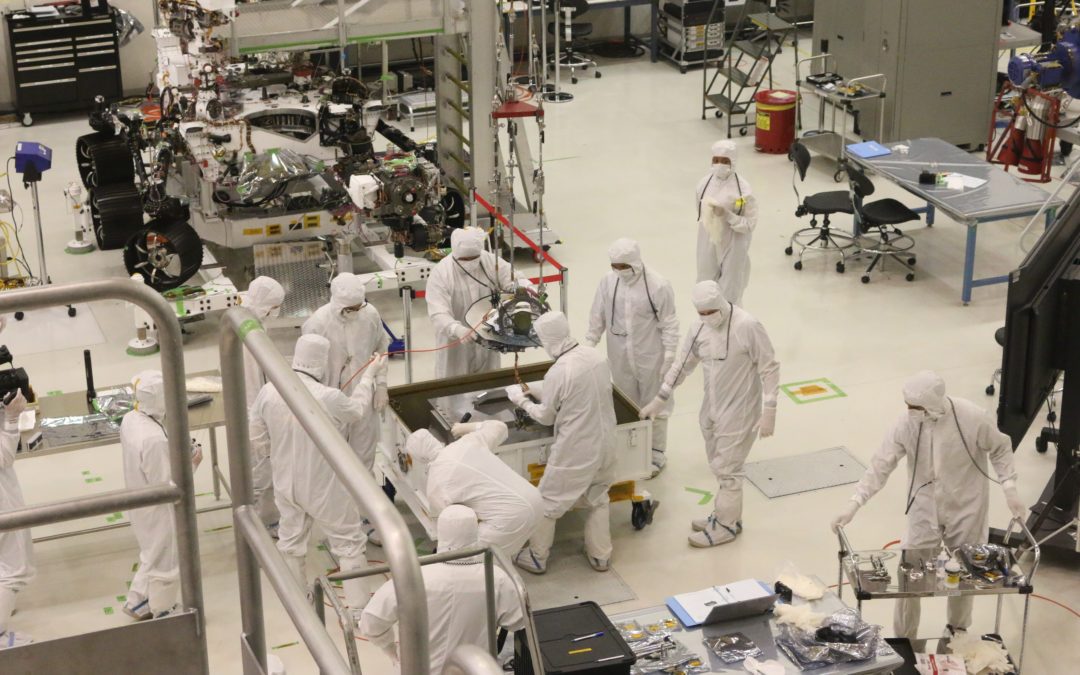

In a medical cleanroom, your filtration system is one of the most important defenses against contamination. In some critical applications, this can be a life-saving system. When designing your cleanroom filtration system, you’ll need to incorporate it with an airflow pattern and your cleanroom HVAC, using the ceiling space efficiently to reach the percentage requirements of your cleanroom classification. Cleanroom filtration is central to all cleanroom components and systems — from the type of medical cleanroom itself to the cleanroom furniture it contains, the employees who work in it and the cleanroom garments they wear. When properly designed, all cleanroom systems should work together to reach your cleanroom classification and create the best environment for you to complete your work. If you need to design a cleanroom filtration system or update your cleanroom filters, Angstrom Technology can help. We design multi-stage HEPA filtration systems for medical cleanrooms and can help you assess and maintain your cleanroom filtration system to ensure your cleanroom is always meeting its classification standards. Give us a call or reach out online to learn more.