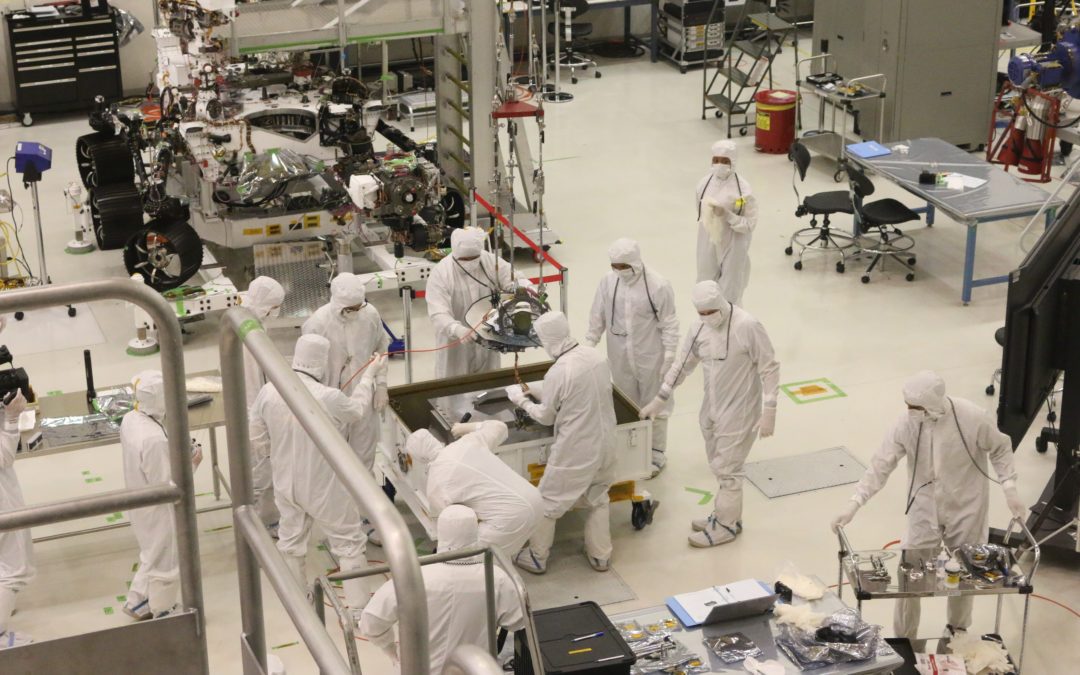

Aerospace cleanrooms are vital for the development, manufacturing, and testing of aircraft and spacecraft, and the computer systems, sensors, and defense technology they incorporate.

Any inconsistency in the controlled environment, such as contaminating particles or fluctuations in humidity, could compromise a piece of equipment or product and lead to failure or injury — neither of which help the facility advance its goals. In order to meet the stringent requirements of their cleanroom classifications, aerospace cleanrooms require the seamless integration of multiple systems and components.

What’s in an aerospace cleanroom? Let’s break it down.

What’s in an Aerospace Cleanroom?

Aerospace cleanrooms are more than just a space to conduct work, research, or testing. They are designed and built to use multiple systems and features to control the environment’s temperature, humidity, purity, pressure, and more. Let’s go through what aerospace cleanrooms need in terms of filtration, HVAC, wall materials, lighting, flooring, furniture and equipment.

Aerospace Cleanroom Filtration

Aerospace cleanroom filtration is essential for reaching your aerospace cleanroom classification standards. Many aerospace cleanrooms fall into ISO 14644-1 Class 7 or lower, meaning they have defined maximum particle allowances during operation. Multi-stage HEPA filters work hard to help purify the air of contaminants, aided by pre-filters and a laminar airflow pattern.

When designing your aerospace cleanroom, you’ll want to plan the ideal path for the air to flow to remove particles and clean the air thoroughly and consistently. Depending on your cleanroom classification, your hourly air change rate will rise with the demand for cleanliness.

Aerospace Cleanroom HVAC

A powerful aerospace cleanroom HVAC is responsible for supplying the space with treated air, purified by your filtration system. Aerospace cleanrooms, especially sensitive applications, require controlled temperature and humidity levels in order to prevent corruption of materials, fuels, or processes.

Aerospace Cleanroom Walls

Aerospace cleanrooms are typically modular HardWall or RigidWall cleanrooms. While both options may reach your cleanroom classification, one may be better suited for your application. HardWall aerospace cleanrooms can reach any standard, even the most restrictive Class 1. They can also be customized to include any special features your cleanroom needs to succeed, and arrive pre-wired and pre-insulated for convenience.

RigidWall aerospace cleanrooms are best for ISO Classes 5-8. They feature crystal clear panels that make an attractive, minimalist frame — perfect for showing your work to executives or investors. An advantage of RigidWall cleanrooms is they are easy to reconfigure and expand as your project evolves.

Aerospace Cleanroom Flooring

When choosing cleanroom flooring for an aerospace cleanroom, it’s important to consider how you’re using the space. For example, epoxy or urethane flooring is a low-cost option that can also be antistatic — essential if you’re working with fine electronics.

Vinyl flooring is another economic choice, but it may wear out quickly if you move a lot of heavy equipment through the space. Epoxy and polyurethane floor systems are more durable in heavy traffic areas and resistant to corrosive chemicals and fuels.

Aerospace Cleanroom Lighting

Aerospace cleanroom lighting is another important system. Many options exist to give you the best visibility for your space and classification. Common aerospace cleanroom lighting systems include teardrop lighting, flat panels, LED grid lighting, and recessed lighting.

If your cleanroom ceiling must prioritize filter/fan units, a smaller but powerful option such as LED grid lighting may be better for you. If you have space to spare, you can opt for the more economical flat panel lighting.

Aerospace Cleanroom Furniture

Cleanroom furniture for aerospace cleanrooms can provide your employees with a workstation, an ergonomic place to sit while they focus on detailed tasks, and anti-fatigue mats for long periods of standing work. The best cleanroom furniture will be adjustable, easy to clean, and made from non particle shedding materials.

Other Aerospace Cleanroom Design Features

Other cleanroom systems, industry-specific equipment, and cleanroom supplies may be necessary to help your aerospace cleanroom be successful. A few examples include a pressurization system, antistatic materials, and a fire suppression system:

- Positive pressure in aerospace cleanrooms can be a useful way to supplement your filtration system by blocking contaminating particles.

- Antistatic cleanroom supplies and materials are essential if you deal with sensitive materials, flammable substances, or fine electronics.

- A fire suppression system can help limit damage if something does go wrong, and protects your employees from workplace hazards.

Is your aerospace cleanroom missing something? Talk to Angstrom Technology. We have everything you need to build and run a high-performing cleanroom environment. From modular panels to flooring, lighting, furniture and more, Angstrom Technology is fully equipped to make your cleanroom a success. Give us a call to learn more.