How Can Custom Cleanroom Designs Adapt to My Industry’s Requirements?

In today’s world, cleanliness isn’t just a virtue – it’s a necessity. Here at Angstrom Technology, we’re experts in tailoring cleanrooms to meet the unique needs of various industrial applications. From automotive to life sciences and beyond, we’ll explore how custom cleanroom designs can be implemented to meet industry requirements and keep businesses thriving.

Discover the Vital Role of Cleanroom Designs

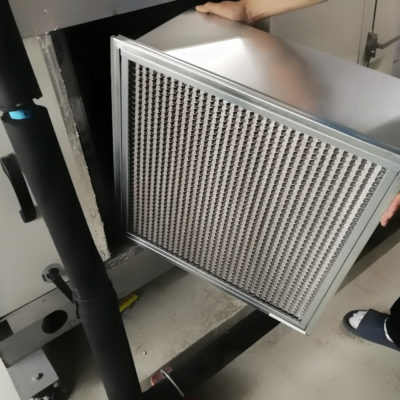

Cleanrooms are controlled environments engineered to minimize contamination from particles, microorganisms, and other impurities by precisely regulating air quality, temperature, humidity, and pressure. Achieving this level of control requires meticulous design, construction, and ongoing maintenance.

Cleanrooms are implemented in a wide array of industries, ranging from pharmaceuticals to aerospace. In some fields, the tiniest of particles or microbes can lead to product defects or health hazards, so cleanrooms have become an invaluable tool.

The need for custom cleanroom designs tailored to industry-specific requirements cannot be overstated. Each sector presents unique challenges, including stringent cleanliness standards and specific regulations. Therefore, a one-size-fits-all approach does not suffice when it comes to cleanrooms.

Attempting to apply a uniform design to vastly different industries risks compromising the quality and safety of products and can result in regulatory non-compliance. Custom cleanroom designs address these challenges head-on by adapting to the precise needs of each industry.

To learn more about specific cleanroom classifications and standards, check out our helpful Classifications & Standards page.

Cleanroom Designs Across Popular Industries:

At Angstrom Technology, we offer dynamic and flexible cleanroom designs, ensuring that your environment aligns seamlessly with the objectives and standards of your industry. We utilize custom designs so you can achieve the highest level of cleanliness, precision, and product integrity.

Below, we will showcase some of the most popular sectors we work with when creating custom modular cleanrooms. Don’t your field? No worries! We work with many companies that differ from what’s listed below. Email or call our team and discover what we can do for you.

Pharmaceuticals

The pharmaceutical industry relies heavily on cleanrooms for drug manufacturing and research. Sterile environments are paramount to ensure product safety and regulatory compliance.

Angstrom Technology Custom Cleanroom Solutions for the Pharmaceutical Industry:

The pharmaceutical industry is subject to heavy government regulation, and pharmaceutical cleanrooms must meet stringent cGMP standards and requirements. You can be assured that Angstrom Technology designs, constructs, and installs the highest-quality pharmaceutical cleanrooms in the business.

Automotive

In the automotive sector, cleanrooms are indispensable for manufacturing sensitive components. Precision is the name of the game, as even a speck of dust can impact the performance of critical parts.

Angstrom Technology Custom Cleanroom Solutions for the Automotive Industry:

Angstrom Technology designs, builds, and installs top-of-the-line cleanrooms to meet the needs of the automotive industry. Our automotive cleanrooms can meet any classification requirements and are ideally suited for automotive innovation, component manufacturing, and quality testing applications.

Aerospace

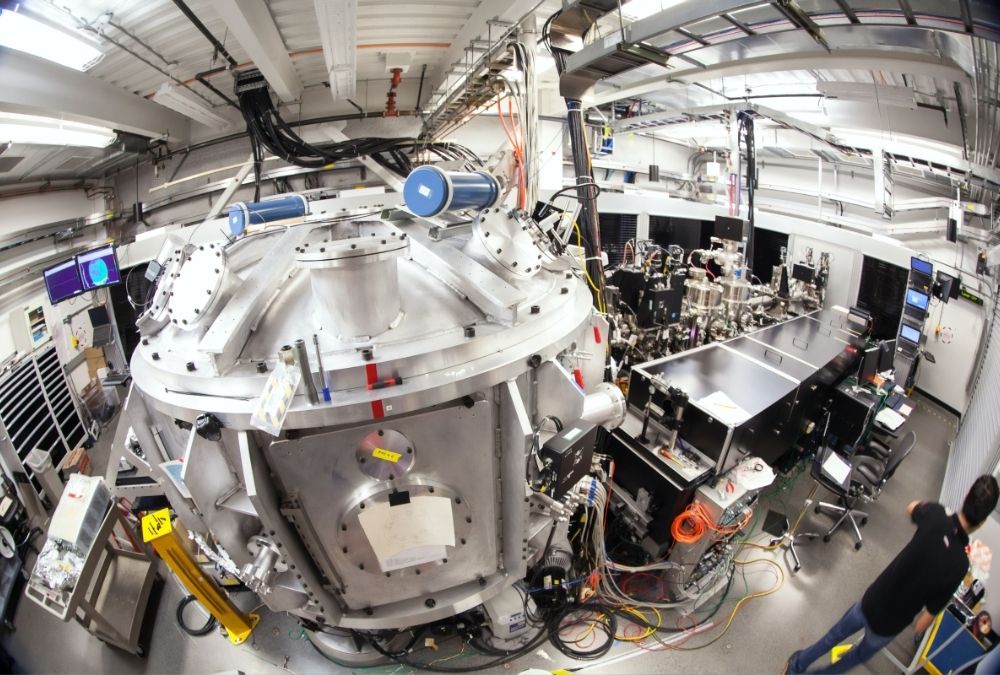

Aerospace companies utilize cleanrooms for the production of aircraft components. The slightest impurity could compromise the structural integrity of these parts and have massive effects on production.

Angstrom Technology Custom Cleanroom Solutions for the Aerospace Industry:

When it comes to the rigorous cleanroom classifications of the aerospace industry, Angstrom Technology creates the best modular cleanrooms available. All of our cleanroom builds comply with US building and safety codes and are complete with the fixtures and systems you need to use right away.

Cell and Gene Therapy

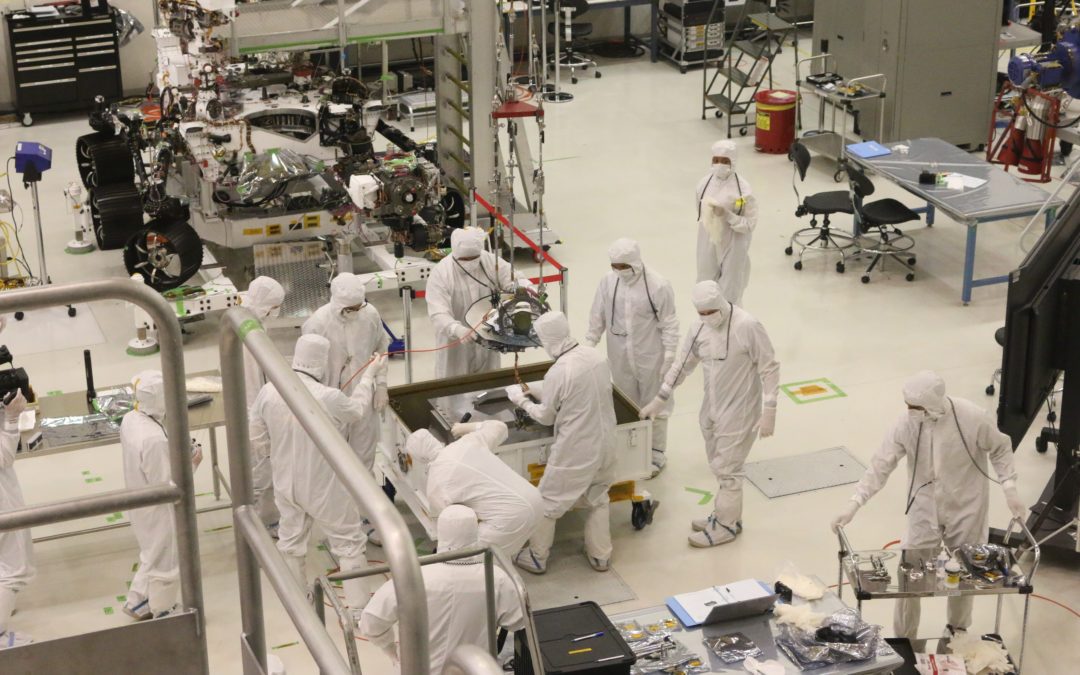

A one-size-fits-all approach to cleanrooms drastically falls short when dealing with the intricacies of cell and gene therapy. These revolutionary therapies involve manipulating and administering living cells and genetic materials, making the need for pristine, contamination-free environments paramount.

Cell and gene therapy have their own distinct set of requirements, including the need for ultra-sterile conditions to ensure patient safety and therapy effectiveness. Custom cleanrooms are designed to tailor to this innovative field’s stringent standards and specialized needs, thereby playing a crucial role in advancing life-saving treatments and ensuring regulatory compliance.

Angstrom Technology Custom Cleanroom Solutions for the Cell and Gene Therapy Industry:

Cell and gene therapies require complex production processes requiring cellular engineering, genetic engineering, growth, and purification. All these operations must be carried out in a controlled environment to ensure safe, reliable, and repeatable results. You can be sure that our cleanrooms meet all the necessary ISO classification requirements.

Life Sciences

Life sciences is a multifaceted field encompassing many applications, from biotechnology and medical device manufacturing to research and development in genetics and microbiology. Cleanrooms play a pivotal role in maintaining the integrity and innovation of this industry.

Angstrom Technology Custom Cleanroom Solutions for the Life Sciences Industry:

The Angstrom Technology Life Sciences Division (ATLSD) has quickly emerged as a leader in cutting-edge products and services for cleanrooms, dry rooms, and cold rooms. We’re dedicated to pushing the boundaries of what’s achievable in the industry, focusing on how integrated teams can provide the best project approach for compliance and success.

Partner with Angstrom Technology for Your Industry-Specific Cleanroom Needs

If you’re seeking tailored cleanroom solutions for your industry, Angstrom Technology is ready to be your dedicated partner in crafting contamination-free environments. Our proven expertise in custom cleanroom designs spans various sectors, ensuring compliance, precision, and product integrity.

Don’t compromise when it comes to the cleanliness and safety of your operations. Reach out to Angstrom Technology today and discover how we can help you meet your industry-specific cleanroom needs!