Life Sciences Division

With so much riding on their projects, the life science industry demands competence, diligence, and attention to detail from its cleanroom partners.

At Angstrom Technology, we understand this responsibility. Our Life Sciences team is comprised of experienced Compliance, Project Management, and Construction Professionals who are free to draw from our extensive network of trade partners to deliver results. Angstrom maintains the freedom to select from the best designers, manufacturers, or labor sources in the world. This independence allows us to propose solutions that are precisely tailored to our clients’ unique requirements delivering world class Compliance, Quality and Value.

Whether your project involves intricate regulatory requirements, tight deadlines, or stringent quality standards, our team is equipped to handle every challenge with precision and efficiency.

Stay in the loop with Angstrom Technology’s Life Sciences Division!

As a national and global company, we possess the capability to provide design-assist, installation, and commissioning and validation services. We work closely with clients, architects, engineers, construction managers, general contractors, and more, ensuring that projects are executed safely with top-notch quality and fully compliant with requirements.

Angstrom Technology boasts in-house technical experts in compliance, ISO levels, cGMP and GMP, cell and gene, CDMO, dry rooms, and environmentally-controlled rooms. This ensures you have access to the full spectrum of choices available in the market.

LIFE SCIENCES CLEANROOM DESIGN

Featured Project

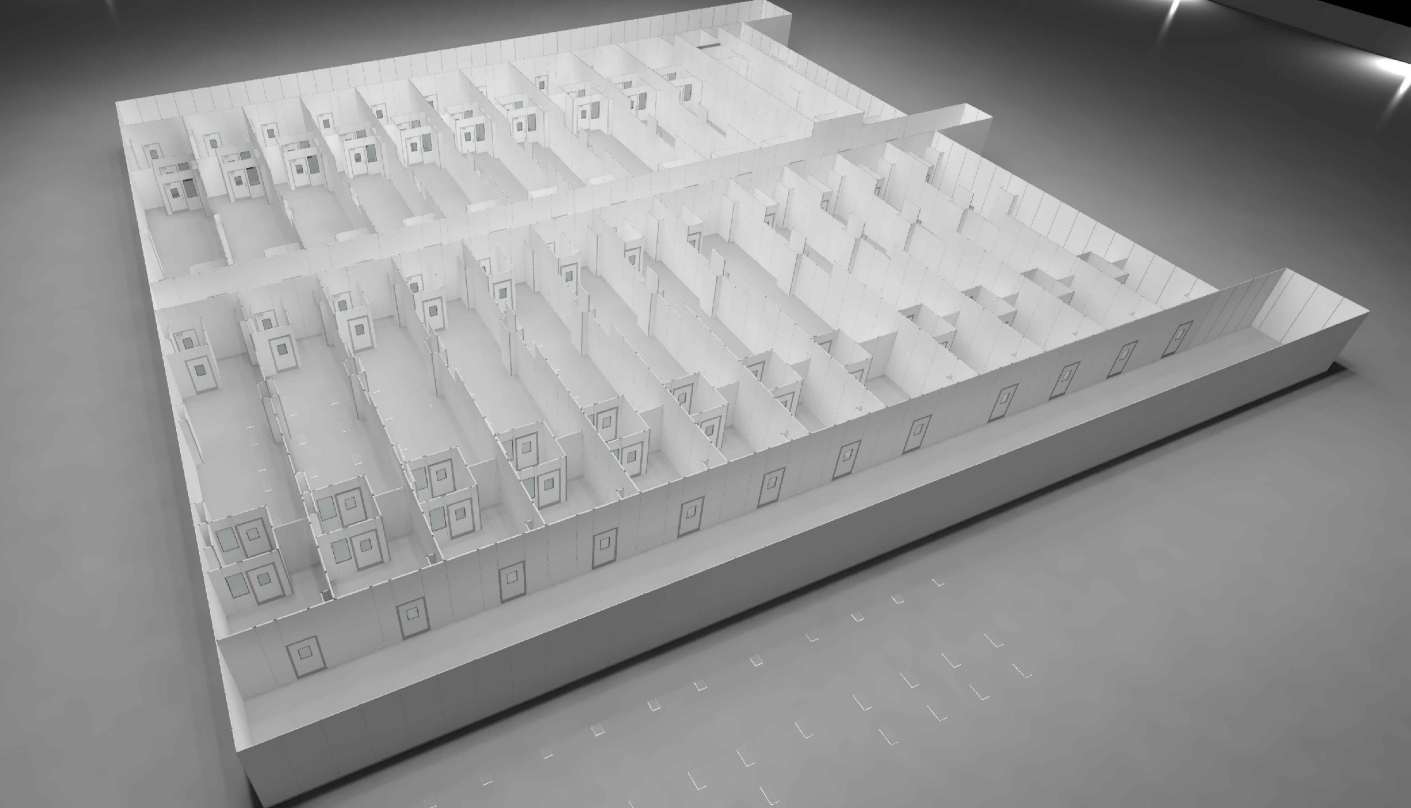

Pharma Cleanroom: From Start to Finish

Our Life Sciences Cleanroom in Action

CLINICAL MANUFACTURING

CLEANROOM

OEM PACKAGING

CLEANROOM

BIOPHARMA

CLEANROOM

PHARMACEUTICAL

CLEANROOM

ADVANCED

RADIOPHARMACEUTICALS

CLEANROOM