Medical Cleanroom Garment Storage: How to Keep Cleanroom Garments Clean

Cleanroom garments are as clean as the places where they are kept. They play a vital role in protecting your cleanroom and employees, so it’s essential to take care of them properly. Let’s dive into the importance of keeping cleanroom garments clean, the difference between reusable and disposable garments, and the cleanroom garment storage you’ll need to always have sterile and fresh items on hand.

Medical Cleanroom Garments

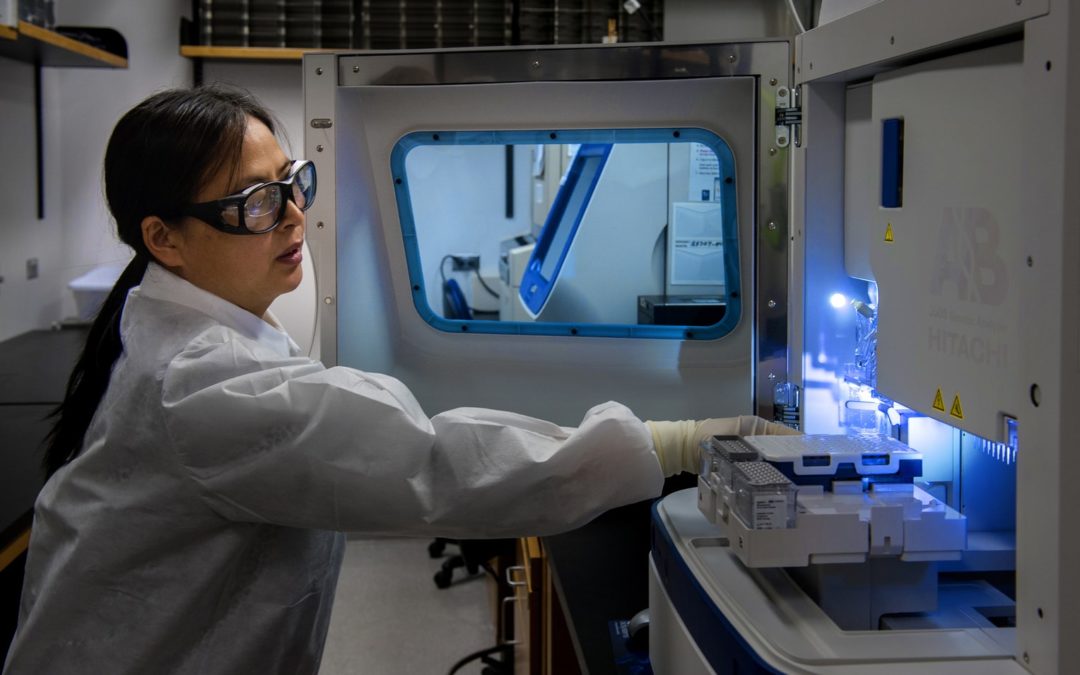

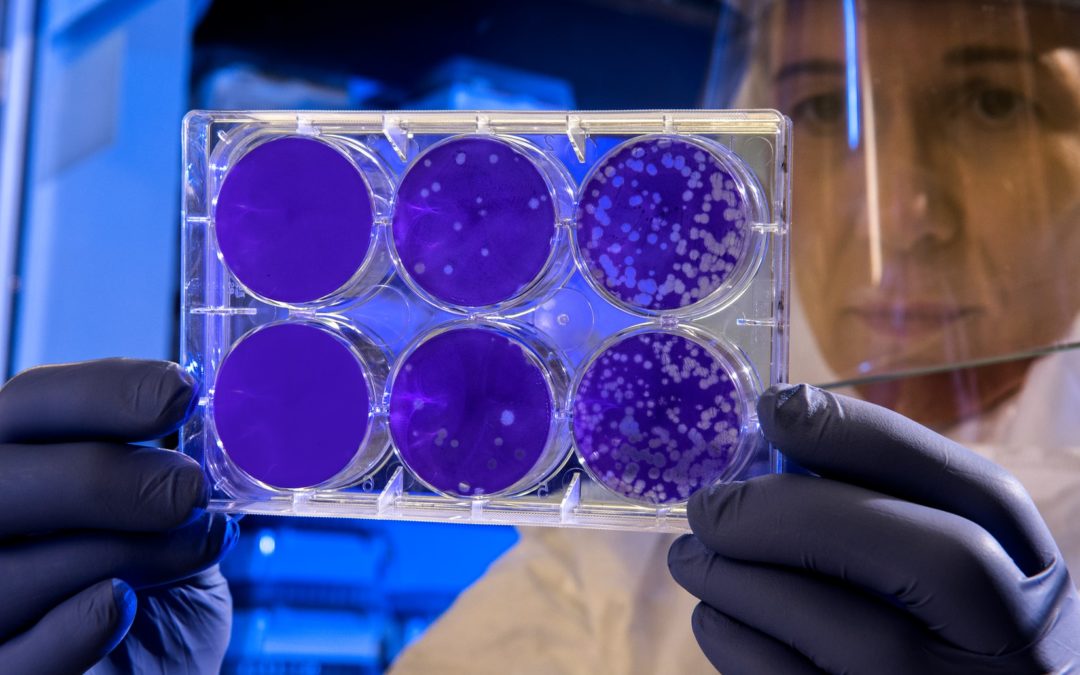

Cleanroom garments are an essential part of medical cleanroom operations. Garments are meant to prevent particles from the wearer from shedding and contaminating the cleanroom. In many medical cleanroom applications, they also protect the wearer from contaminants or harmful substances.

Wearing garments outside of the sterile environment of a cleanroom can attract contaminants. The inside of the garment is also contaminated by particles from the wearer. It’s important to use clean garments each time a worker enters the cleanroom environment to protect sensitive products and processes within the controlled space from these particles.

Properly cleaning protocols and cleanroom garment storage — whether for reusable garments or new disposable ones — are important to protect workers and the cleanroom from possible contamination. If garments are contaminated, both the integrity of your work and the safety of your employees are at risk. Particularly in medical cleanrooms, there’s no room for error. Contamination could interfere with test results, corrupt substances, compounds or devices, and potentially endanger patients’ lives.

Reusable vs. Disposable Cleanroom Garments

Reusable cleanroom garments can be cleaned in-house or by a third-party cleaning service. Disposable garments are typically meant to be worn once, though it depends on the product and the manufacturer’s recommendations.

Reusable Cleanroom Garments

Reusable garments must be washed with a special process (and extremely hot water) to remove particles and sanitize them safely without compromising or degrading the protective material. If cleaned by a third party, you’ll also need to ensure transport to your facility is sterile and that no contaminants are introduced to your cleanroom from an outside source.

Disposable Cleanroom Garments

Some medical cleanrooms with critical sterilization protocols and stringent requirements opt for disposable garments because it is the safest and most cost-effective option. Disposable garments should be high quality so they are comfortable for workers and won’t break down when in use. Be sure to buy quantities and sizes that are appropriate for all personnel.

Many medical cleanrooms use a combination of both reusable and disposable garments. For example, gowns and face shields may be cleaned, sanitized, and reworn, but disposable nitrile gloves and boot covers are replaced after each use. All garments, whether reusable or disposable, must be kept in appropriate cleanroom garment storage.

Medical Cleanroom Garment Storage

Adequate cleanroom garment storage is just as important as how the garments are used. Cleanroom garments are stored in the gowning room for immediate use, though your facility may also have an area to keep overstock items.

In the gowning room, cleanroom garment storage takes the form of specialized cabinetry, shelves, and containers arranged in a way that facilitates the gowning procedure.

A proper gowning procedure will ensure your employees suit up properly without contaminating their garments. This process involves cleaning exposed skin before donning garments in the correct order to contain any particles and not contaminate other items or parts of the garment.

Medical cleanroom cabinets and shelves are used to display all garments for easy access as well as store them before use. Garments for use in critical applications may need to be housed in their own HEPA-filtered cabinets or showered with air to dislodge any particles that may have adhered to the material.

Cleanroom garment storage may also need anti-static safeguards in place to prevent the attraction of particles due to imbalanced charges. All new garment items must be sealed and packaged individually to prevent contamination.

The purpose of cleanroom garment storage is to make all items accessible to employees while staying isolated from contaminating particles as much as possible. The use of sticky mats, air showers, and benches can help limit contamination, along with the enforcement of the proper gowning procedure.

All used garments must be placed in separate cleanroom garment storage to ensure no contamination reaches the fresh, untouched garments. Until they can be cleaned and returned to the gowning room or disposed of responsibly, there should be no contact with the areas used for clean garments.

Cleanroom garment storage is essential to protecting your operations and workers. Does your cleanroom have appropriate garment storage space? If not, give us a call. We’re happy to help design and install the solutions that will make your cleanroom cleaner.