Cell and gene therapies have become more recognized as viable forms of treatment for serious, life-threatening illnesses. However, there’s still quite a bit of information to learn about them — including the controlled environments in which they’re tested, produced, and administered.

If you’re hoping to learn more about cell and gene therapy cleanrooms, you’ve come to the right place.

10 Frequently Asked Questions About Cell and Gene Therapy Cleanrooms

Below is a list of 10 of our most frequently asked questions about cell and gene therapy cleanrooms, along with their respective answers.

1. What Is Cell and Gene Therapy?

Cell and gene therapies are two forms of regenerative medicine. They both have similar goals of lessening or curing a serious illness or disease, but there are some differences in how they’re implemented.

- Cell therapy involves injecting live, intact cells into a patient to lessen or cure their illness. These cells may be from the patient themself (autologous) or from a donor (allogeneic).

- Gene therapy involves injecting genetic material into a patient to change how a single protein or group of proteins is produced by the cell, ultimately lessening or curing their illness.

Cell and gene therapies are gaining recognition in the field of medicine as safer, more personalized, less invasive, and potentially more effective ways to treat life-threatening diseases.

2. What Are the Unique Risks Associated with Cell and Gene Therapy?

Cell and gene therapies are highly sensitive applications – more so than many other medical or medicinal functions. The many processes that go into testing, producing, and applying them can be manipulated easily if not completed with extreme caution.

Think of tasks like cellular and genetic engineering, growth, and purification. It’s critical that the results of those tasks are safe, effective, and reproducible to ensure treatment viability and patient safety.

3. What Is a Cell and Gene Therapy Cleanroom?

Since cell and gene therapy applications are so high-risk, a controlled operating environment is necessary. A specially designed cleanroom can offer specialized control, cleanliness, equipment, and whatever else is needed to ensure treatment viability and patient safety.

Cell and gene therapy cleanrooms have unique features compared to other types of cleanrooms. Many of these unique features are described in the answers to the questions below.

4. What ISO Classification Do Cell and Gene Therapy Cleanrooms Require?

Typically, cell and gene therapy cleanrooms need to meet ISO Class 5-7 standards. However, this can vary depending on what particular task is being performed and how much environmental control it requires.

ISO classification can change from cleanroom to cleanroom, or from one of a cleanroom’s zones to another, or within a designated work chamber inside of the cleanroom. It can change to a level of less or more control.

5. What Other Quality Standards Do Cell and Gene Therapy Cleanrooms Need to Meet?

ISO standards aren’t the only set of quality standards that cell and gene therapy cleanrooms require. In many cases, they need to comply with GMP (or cGMP) standards as well.

Good Manufacturing Practice (GMP) and Current Good Manufacturing Practice (cGMP) are two quality management systems that are enforced by the U.S. Food and Drug Administration. They’re used by medical and pharmaceutical manufacturers to help minimize the chances of microbiological, particulate, and pyrogen contamination during the preparation and sterilization of medical devices and medicines.

We have a few blogs that provide more specifics on GMP standards. You can check them out through these links:

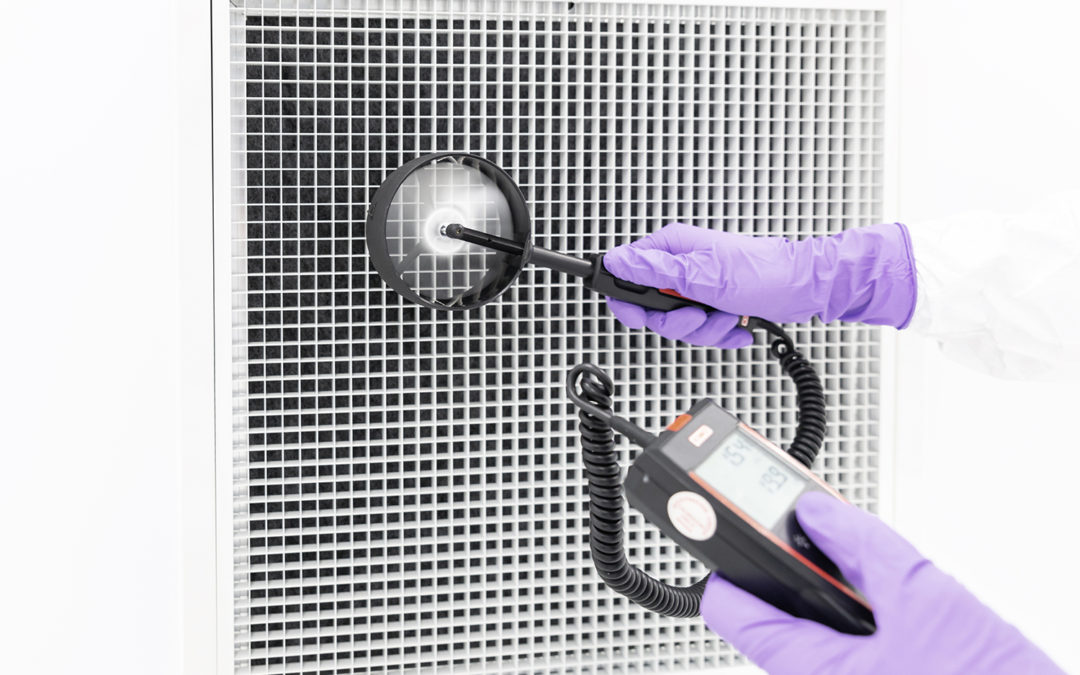

6. What Types of Special Equipment Do Cell and Gene Therapy Cleanrooms Require?

All cleanrooms require specialized equipment to meet the demands of their particular industry and application. Cell and gene therapy cleanrooms are no different. Some of their unique pieces of equipment include:

- Biosafety cabinets: enclosed workspaces that utilize laminar airflow to filter out contaminants and fumes.

- Incubators: devices that create the ideal environment for growing and maintaining cell and gene cultures.

- Refrigerators: devices used to store cell and gene cultures in the cold temperatures they need to survive for short periods of time.

- Freezers: devices used to store cell and gene cultures in the freezing temperatures they need to survive for extended periods of time.

- Centrifuges: machines that isolate strains of DNA or cells from body fluid.

You can learn more about these types of equipment, as well as the risks that are associated with them, in this blog article.

7. What Type of Cleanroom Is Best for Cell and Gene Therapy Applications?

Since cell and gene therapy cleanrooms need a lot of environmental control, a HardWall cleanroom solution is usually the best option. They offer a level of control against contamination, temperature, humidity, and more that other types of cleanrooms just aren’t designed for.

8. What Type of Pressure Is Needed In Cell and Gene Therapy Cleanrooms?

It’s common for cell and gene therapy cleanrooms to be designed and installed as cell and gene therapy cleanroom suites. This means that the larger cleanroom facility contains multiple separate cleanroom zones.

Within these zones, a cascading (or differential) pressure effect is employed. This means that the most stringent cleanroom zone has the highest level of pressure, and that the least stringent cleanroom zone has the lowest level of pressure. This pressure design is highly intentional, so that contaminant particles cannot flow into the cleanest, most controlled cleanroom zone.

9. Are HEPA or ULPA Filters Best for Cell and Gene Therapy Cleanrooms?

ULPA and HEPA filters are both effective at removing airborne particles from the cleanroom environment. However, ULPA filters provide the best filtration for most cell and gene therapy processes.

ULPA filters are 99.999% efficient at removing particles 0.12μm or larger, while HEPA filters are 99.999% efficient at removing particles .3μm or larger. ULPA filters’ ability to filter out those smaller particles gives them the upper hand. However, some cell and gene therapy cleanrooms do just fine with a HEPA filter.

10. Can You Provide an Example of a Cell and Gene Therapy Cleanroom Project?

Sure thing! In 2021, our UK division – Connect 2 Cleanrooms – designed, built, and installed a cleanroom suite for RoslinCT — a leading cell therapy contract development and manufacturing organization in the UK.

The cell and gene therapy cleanroom suite was installed within a two-story building and included 33 internal rooms. It now operates with high performance and control on a day-to-day basis to help healthcare professionals test and manufacture life-saving treatments.

Some special features of the cleanroom include:

- ISO 5 classification (equivalent to EU GMP Grade B)

- HEPA filtration with 79no. air changes per hour

- Vaporized hydrogen peroxide (VHP) cabinets

- Integrated medical gas systems

- Cryostorage

- Fire-rated active pass-through chambers

To learn more about this project and see photos and video of the finished result, visit this project page.

Have More Questions? Contact Angstrom Technology

If you have more questions about cell and gene therapy cleanrooms, or you’re ready to design and install one of your own, don’t hesitate to reach out. We’d be happy to provide you with the answers or solutions you need.