Explore Our Blog

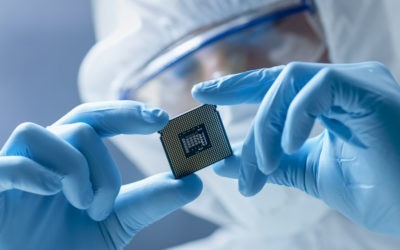

How to Set Up a Semiconductor Manufacturing Cleanroom

Semiconductors are extremely sensitive materials. So without a controlled cleanroom to manufacture the chips in, you risk contamination that could lead to various production issues and product failures. If your facility manufactures semiconductor chips for...

Medical Cleanroom Technology that Aids Surface Sterilization

In order to keep operators and consumers safe, medical cleanrooms have some of the most stringent cleanliness requirements. Depending on whether they’re used for medical research, medical device, or pharmaceutical applications, their ISO standards can range from ISO...

Cleanroom Classification FAQs

Cleanroom classification is often one of the most confusing parts of designing and building a cleanroom. However, it’s also one of the most essential parts, so it’s important that you understand all the relevant information. If you’re installing a cleanroom for the...

Understanding Cleanroom Costs by Type

If your facility needs a controlled space for one or more of its operations, you may be looking into purchasing a cleanroom. However, while doing your research, you may find yourself stuck on which type of cleanroom is the best investment for you: SoftWall, HardWall,...

How to Choose a Fan Filter Unit for your Cleanroom

In order to ensure your facility is meeting required cleanliness standards, fan filter units (FFU) are a critical component of your cleanroom design. Let’s explore more about fan filter units: how they work, what types there are, and how to choose the right one for...

Are Modular Cleanrooms Environmentally Friendly?

Manufacturers and production facilities across the nation are on a continuous search for sustainable solutions. Of course, sustainable solutions help production facilities, labs, and fabrication plants do their part in protecting our environment and natural resources,...

4 Questions to Ask Before Starting Automotive Cleanroom Construction

There’s a lot of planning involved in automotive cleanroom construction. From layout design to operational components, you need to figure out what you need and how to implement it before you start building. Many experienced cleanroom designers and engineers have...

4 Microelectronics Manufacturing Applications that Rely on Cleanrooms

Microelectronics manufacturing often involves delicate materials and occasionally toxic substances that require special care for handling and storage. Manufacturing equipment is also highly sensitive and generates heat which must be controlled. For applications in...

How to Achieve Aseptic Conditions in Medical Cleanrooms

The ability to achieve aseptic conditions is invaluable in many medical cleanrooms and other healthcare applications. Let’s talk about what aseptic conditions are — and are not — as well and look at what you need to design an aseptic cleanroom. What are Aseptic...

5 Ways to Improve Efficiency in Aerospace Cleanroom Design

In the aerospace industry, we’re always looking for ways to improve efficiency in your cleanroom facility. Strategies that help you achieve the same or better results at a lower cost, boost efficiency, either by reducing energy expenditures, lowering operating costs,...

5 Types of Cleanrooms that Use Air Showers

If you own and operate a cleanroom, you know that people are the single largest source of entering contaminants. Cleanrooms serve to limit potential contamination from reaching your work, but even constant filtration, garments, and gloves can only do so much — there...

5 Considerations for Your Plastics Injection Cleanroom Design

Your new plastics injection cleanroom needs to be a highly efficient machine. Every component should be considered in the design to work together to help you achieve your goals. This includes your cleanroom classification requirements and other needs and wants for...

Get Instant Access To Our Cleanroom Design Guide

The Most Comprehensive Guide for Cleanrooms and Modular Offices