Explore Our Blog

Medical Cleanroom Garment Storage: How to Keep Cleanroom Garments Clean

Cleanroom garments are as clean as the places where they are kept. They play a vital role in protecting your cleanroom and employees, so it’s essential to take care of them properly. Let’s dive into the importance of keeping cleanroom garments clean, the difference...

Modular Cleanroom Building Process

The modular cleanroom building process is as multifaceted as your industry and as vital as your work, which is why finding with the right team to help you with cleanroom design, construction, and installation is crucial. They’re responsible for making sure your...

HardWall vs. RigidWall Aerospace Cleanrooms

When it comes to the high stakes of the aerospace industry, the type of cleanroom you choose matters. Your cleanroom structure defines the layout of your space and determines the level of control you can achieve over environmental factors like temperature, humidity,...

Medical Cleanroom Design Tips: Cleanroom Windows

When it comes to medical cleanroom design, you are constrained by the cleanroom classification you must meet. That said, every medical cleanroom has its own unique application and processes that require an accommodating design. One common design feature of a medical...

3 Benefits of Positive Pressure Cleanrooms for Aerospace & Defense Industries

Pressurized cleanrooms are used in a range of industries and applications. Varying levels of pressure determines the way air naturally moves in a space. High and low pressure, or positive and negative pressure, can be used as a tool in cleanroom environments to...

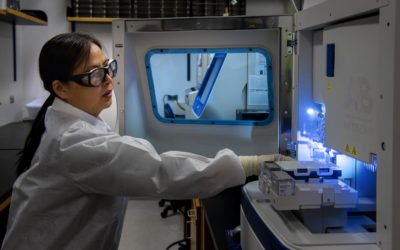

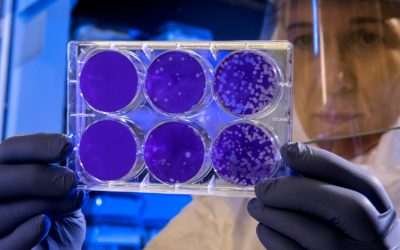

3 Types of Medical Cleanrooms

Medical cleanrooms are vital for the work of finding medical solutions, developing vaccines and treatments through pharmacological products, and manufacturing life-saving medical devices, among other important applications. Three main types of medical cleanrooms are...

How to Upgrade your Cleanroom

As Greek philosopher Heroclitus said, “There is nothing permanent except change.” While the conditions in your cleanroom are designed to stay the same, your work rarely does. If your project needs are evolving, you might find yourself needing to meet new cleanroom...

What’s the Deal With Segmented Cleanrooms?

An important part of cleanroom design is the choosing the best layout to suit your unique application. If your cleanroom has the challenge of needing to meet changing requirements or different levels of cleanliness, air changes, or pressure for different stages of...

3 Common Types of Cleanrooms

If you know you need a controlled space to operate your business, a cleanroom is designed to help you achieve a completely clean environment to work, while managing environmental factors like temperature, humidity, static, and pressure. Whether you’re manufacturing,...

HVAC System Requirements for Aerospace Cleanrooms

Aerospace cleanrooms require a high level of control. They can range from an ISO 14644-1 Class 5-7, which have vastly different requirements. At a minimum ISO Class 7, the cleanroom will require about 60-90 air changes per hour and need to filter out a range of...

3 Medical Industries that Use Negative Air Pressure Cleanrooms

It’s a well-known natural process for air to flow from high to low pressure. Examples of this are found around us every day. Wind and weather are formed from the uneven heating of the earth’s surface which generates pockets of high and low pressure air. If you’ve ever...

Static Control for Medical Device Cleanrooms: Everything You Need to Know

Even with a powerful HVAC system, a multi-stage HEPA filtration process, and thorough cleaning procedures, contaminants can still threaten a controlled cleanroom environment. Static electricity is common everywhere we live, but in a cleanroom it can be unpleasant,...

Get Instant Access To Our Cleanroom Design Guide

The Most Comprehensive Guide for Cleanrooms and Modular Offices