HardWall Cleanroom Features

We’ve already talked about SoftWall cleanroom features (check that blog out if you haven’t yet!). Now, let’s move on to HardWall cleanroom features. We’ll discuss what they are, what special features and capabilities they provide, and what benefits they could bring to your cleanroom application.

What Are HardWall Cleanrooms?

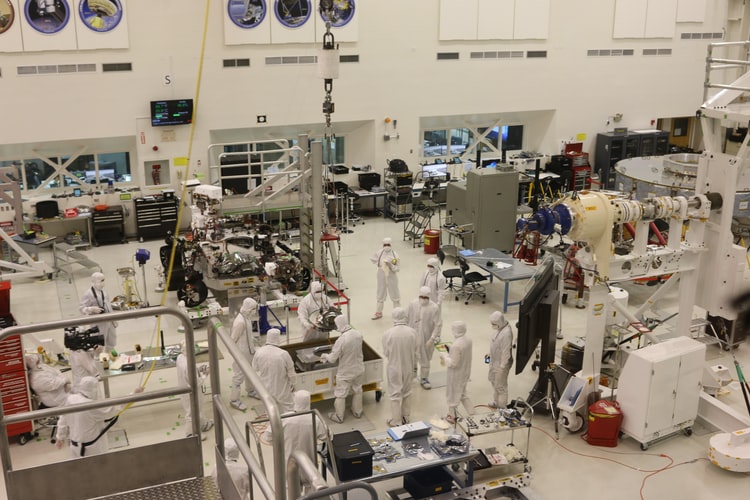

HardWall cleanrooms are built with prefabricated solid panels and provide the highest level of environmental control. Known for meeting stringent cleanliness requirements and maintaining peak performance for years, they’re durable, adaptable, solid-walled cleanrooms that can comply with any ISO standard or classification.

Due to these characteristics, HardWall cleanrooms are great choices for industries and applications that require strict control over contamination, temperature, humidity, static, pressure, sound, fire protection, and more. At Angstrom Technology, we’ve worked on an extensive list of HardWall cleanroom projects in industries involving semiconductors, pharmaceuticals, aerospace, cell and gene therapies, and more.

HardWall Cleanroom Features

Depending on each specific application, every HardWall cleanroom is custom designed and constructed based on customer needs. However, they all have some of the same basic features, which are discussed in the following three sections.

HardWall Cleanroom Materials

The most prominent material within HardWall cleanrooms is their panelized wall systems. We’ll describe those, as well as some other necessary materials, below:

- Wall Panels – HardWall cleanroom wall panels fit within the framework and are prefabricated and non-progressive — meaning they’re designed for easy removal without disturbing adjacent panels and for minimizing contamination possibilities. They’re composed of a panel core (gypsum laminated to a polystyrene core or aluminum honeycomb), and finished with a stainless steel, fiberglass reinforced plastic (FRP), uPVC, painted aluminum, or smooth vinyl finish.

- Roof Deck – The roof deck is secured to the perimeter wall panels and spans over the HardWall cleanroom, creating a standalone, modular cleanroom structure. The deck supports the ceiling system and all its components, but can also be designed to meet load bearing requirements. It’s composed of a 20-22 gauge ribbed steel deck.

- Ceiling System – HardWall cleanroom ceiling systems can be a robust T-grid ceiling system or a panelized walkable ceiling, both of which hold the cleanroom’s fan filter units (FFUs) and lights.

- Framework – The framework is the modular wall support system that provides a HardWall cleanroom’s structural integrity. The framing components are made of a durable, extruded aluminum and stainless steel, which has a powder-coated or clear-anodized finish.

- Entrances – HardWall cleanrooms are compatible with various types of entrances, such as swing doors, overhead roll up doors, automatic or manual sliding doors, and more.

HardWall Cleanroom Sizes

HardWall cleanrooms are available in any size and configuration. While standard prefabricated panels are 4’ wide nominally and come in 8’, 9’, or 10’ heights, many cleanroom manufacturers allow you to choose the cleanroom size that fits your process the best.

HardWall Cleanroom Standards

Due to their high level of environmental control, HardWall cleanrooms can meet any ISO standard. They’re naturally suited for ISO Classes 5-8, but with additional equipment and technologies, they’re capable of meeting even stricter requirements.

Benefits of HardWall Cleanrooms

Out of all three types of cleanrooms, HardWall cleanrooms are generally the most popular. Below are some of the most common reasons our customers at Angstrom Technology have chosen HardWall cleanrooms for their facilities:

Great Environmental Control

With HardWall cleanrooms, environmental control doesn’t stop at preventing particle contamination. Instead, you’ll enjoy various other forms of strict control — from temperature and humidity, to static and pressure, to sound and fire protection. This high level of control enables your cleanroom to meet whatever ISO standard is required for your application.

Easy Modification & Expansion Capabilities

HardWall cleanrooms are constructed with a prefabricated, modular construction design, which allows for multiple configurations and the ability to modify and expand spaces quickly and easily. You’ll be able to reconfigure to meet changing cleanroom needs, expand as your company grows, and upgrade with new technologies as they become available. This makes a HardWall cleanroom a sound, long-lasting investment for your facility.

Unmatched Durability

With reliable wall panel composition, robust ceiling systems, and dependable structural framework, HardWall cleanrooms are highly recognized for their outstanding durability and longevity. Their systems are made to have structural integrity and be self-supporting, so they will not sag. In addition, because of their specific non-porous finishes, the systems will not warp, rust, or corrode, so you’ll be able to enjoy long-lasting performance — even if your space is reconfigured multiple times to accommodate your facility’s needs.

Simple Maintenance

HardWall cleanrooms are one of the easier types of cleanrooms to maintain. Their non-porous surfaces and specific finishes on modular components make routine cleaning and testing a breeze. That way, you can spend less time and energy worrying about maintaining the space, and more time and energy actually using it to drive production and profit.

Interested in installing a HardWall cleanroom in your facility, or have questions about which type of cleanroom is right for your application? Contact Angstrom Technology. Our experts have experience designing, installing, and maintaining all types of cleanrooms, for various industries — and we’d be happy to get started on one for you!