Explore Our Blog

Fan Filter Units and Air Handling Units. What’s the Difference?

If you're considering different options for filtering and treating the air in your cleanroom, you've likely come across fan filter units (FFUs) and air handling units (AHUs). What's the difference, and how can you design a cleanroom filtration system that will offer...

How to Decide on the Right Wall Material for Your Cleanroom

If you’re working on a technical specification for your new cleanroom design, you’ve likely noticed different types of cleanroom wall materials in the market. Unless you have experience with all the different types of cleanrooms, you might not yet know which cleanroom...

Building a Battery Dry Room

Many materials and processes used in battery production are susceptible to moisture damage. For that reason, humidity control is critical in a battery dry room. The experts at Angstrom Technology can create a stable low dewpoint production environment to meet your...

5 Reasons You Need a Modular Cleanroom

At Angstrom Technology, our modular cleanrooms are a popular choice for organizations looking to create cleanroom space quickly. Here are just 5 reasons you need one. 1. Flexibility to extend or relocate If you need some cleanroom space right now but know...

RigidWall Cleanroom Features

Planning to install a new cleanroom in your facility? One of your first steps should be to figure out which type of cleanroom is the best fit: SoftWall, HardWall, or RigidWall. All of these have great features and performance capabilities, but one of them may work...

What Is the Equivalent ISO Class for cGMP Areas?

At Angstrom Technology, we get asked a lot what the equivalent ISO class for a cGMP area is. Particularly from organizations at the start of a cleanroom project. Here, we answer that question for you. The International Standard for cleanrooms and associated controlled...

The CHIPS Act: Designing your Semiconductor Cleanroom

On August 9, 2022, President Biden passed the CHIPS Act. What’s that? We’re here to fill you in. The CHIPS Act CHIPS stands for Creating Helpful Incentives to Produce Semiconductors for America Act. The investment promises $50 billion to domestic R&D and...

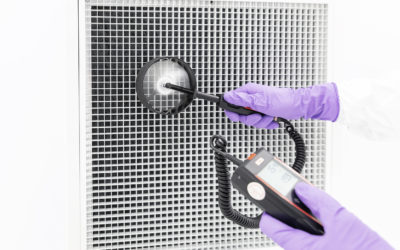

The Cleanroom Commissioning Process: Explained

Before a cleanroom is determined safe and viable for use, it typically will undergo a commissioning process. What’s that? We’re here to fill you in. What Is Cleanroom Commissioning & Why Is It Important? Cleanroom commissioning is the practice of verifying that a...

GMP vs. cGMP Standards for Cleanrooms

Understanding cleanroom quality standards can be tricky. There are various systems, all of which have different themes, criteria, guidelines, and regulations. One distinction that can be particularly challenging is the difference between GMP and cGMP standards. These...

Cleanroom Design: Post-and-Panel vs. Seamless Cleanroom Wall Systems

The materials you use to build your cleanroom have a lasting impact on its cleanliness, performance, durability, and appearance. Arguably the most important of these materials is the cleanroom wall system you choose. Let’s take a look at two of the most common types...

Dedicated vs. Integrated Cleanroom HVAC Design

Environmental control is the staple of effective cleanroom design and performance. In order to ensure safe and controlled operations can take place, airborne particles of a certain size must be caught and removed from the cleanroom environment. However, there’s more...

Cell and Gene Therapy Cleanroom FAQs

Cell and gene therapies have become more recognized as viable forms of treatment for serious, life-threatening illnesses. However, there’s still quite a bit of information to learn about them — including the controlled environments in which they’re tested, produced,...

Get Instant Access To Our Cleanroom Design Guide

The Most Comprehensive Guide for Cleanrooms and Modular Offices