Cleanroom Terminology 101

If you’re new to cleanrooms, the terminology surrounding them might seem like a foreign language, but it’s crucial to understand in order to design and run an effective cleanroom. Here’s a run-down on the most basic terms you need to know when it comes to cleanroom terminology.

What’s a cleanroom?

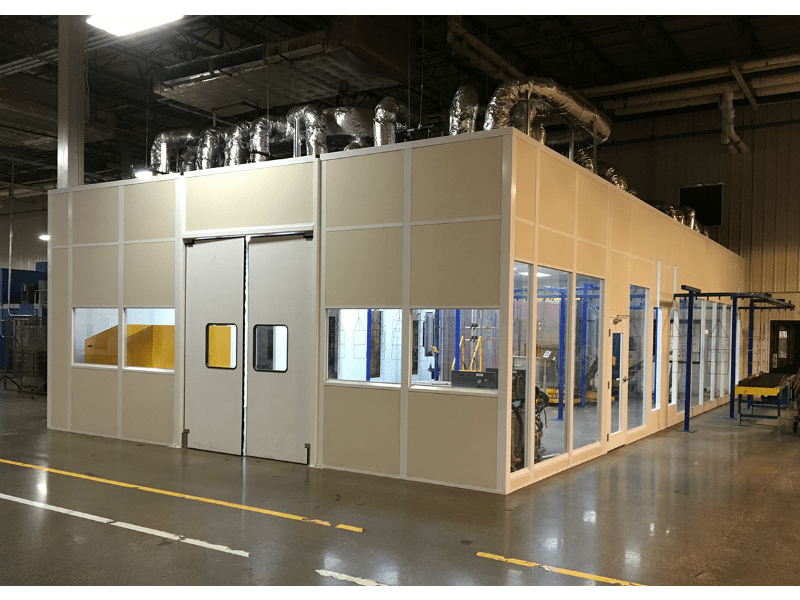

A cleanroom is a controlled environment that limits contamination and particles, as well as temperature, humidity, static, and other factors, in some cases. Specialized air circulation and filtration systems filter out particles and contaminants from the air. Cleanrooms can be used in a variety of industries and for a variety of applications, including storage, manufacturing, and testing and analysis. Read more about the various types of cleanrooms here.

What’s classification?

Cleanroom classification is a way of identifying the level of contamination control within a cleanroom. The classes are defined by the number of particles of certain sizes that are present in a cubic foot of air within the cleanroom. Cleanrooms are usually classified to either the ISO standard or Federal Standard 209E. Read more about cleanroom classifications here.

What’s ISO?

ISO stands for International Organization for Standardization, which is an international scientific body that creates standards for organizations for manufacturing, organizational success, and workplace conditions, among other things. ISO has created a standard for cleanroom classification that classifies cleanrooms into eight classes. Read more about the cleanroom ISO standards here.

What’s certification?

Certification is a process of testing and verifying cleanroom environmental controls to ensure that they meet the standard required for the industry and the application. This includes testing of the major components including filters, air flow equipment, HVAC, ionization equipment, etc. Read more about cleanroom certification and validation here.

Need to learn more about cleanrooms or need help designing one? Contact the cleanroom experts at Angstrom Technology. For more on cleanroom terminology, check out our cleanroom glossary.