Modular cleanrooms are popular in many industries because of their versatility, durability, and cost effectiveness. They can offer several advantages for the plastics industry to help companies streamline their operations and meet their classification requirements effortlessly.

Let’s take a look at 5 specific advantages plastics industry cleanrooms can enjoy by going modular.

#1 Modular Cleanrooms are Convenient and Easy to Assemble

Modular cleanrooms are designed to streamline the cleanroom design and construction process. Fabricated off site to your exact specifications, modular panels come pre-wired and insulated, with all the special features you need to make your project a success. They can be assembled according to a detailed set of instructions and integrated with your cleanroom systems — providing you with a fully functional cleanroom with minimum disruption to your facility’s operations.

In the plastics industry, efficiency is key. With a short turnaround time on many projects, having a powerful, convenient cleanroom option that can be designed, built, and installed quickly can make all the difference. Modular cleanrooms provide all the environmental control and stability you need, without the lengthy and expensive process of traditional construction.

#2 Modular Cleanrooms Can be Reconfigured or Expanded

Another great advantage of going modular, is that this cleanroom type can easily be reconfigured, expanded, condensed, or even moved if your project needs change. Modular panels allow for the ultimate flexibility of cleanroom construction — without sacrificing quality. By adding or taking away panels, you can reshape your space to fit in your existing structure, around mounted equipment, and utilize your building’s systems.

Modular cleanrooms used for application in the plastics industry must be able to adapt to changing project demands or goals. A cleanroom that can be easily modified to meet new requirements or be reconfigured to accommodate new equipment, personnel, or products, not only makes it easier to get started on whatever’s next, but it can also save your company money.

Instead of building new cleanrooms to conform to the classification standards, industry requirements, and cleanroom systems of each new project — one modular cleanroom can do it all.

#3 Modular Cleanrooms Can Meet Any Classification Standard

Modular cleanrooms can adapt to any cleanroom classification or industry standard for cleanliness and environmental control. There are three main types which can meet the needs of your classification and application:

- HardWall Cleanrooms: capable of reaching any ISO classification — even the most stringent Class 1

- SoftWall Cleanrooms: lightweight and flexible cleanroom construction ideal for ISO Classes 4-8

- RigidWall Cleanrooms: crystal-clear modular panels best suited for ISO Classes 5-8

In the plastics industry, cleanrooms must be able to control temperatures and environmental conditions to maintain large machinery that generates significant heat. Plastics cleanrooms must be able to ensure sterility during the manufacturing and packaging of plastics products.

Especially for the development of plastics for critical uses, like medical devices, extreme care and cleanliness is essential for consumer safety. Modular cleanrooms are able to provide the sterile environment these applications need to be successful.

#4 Modular Cleanrooms are Built to Withstand Anything

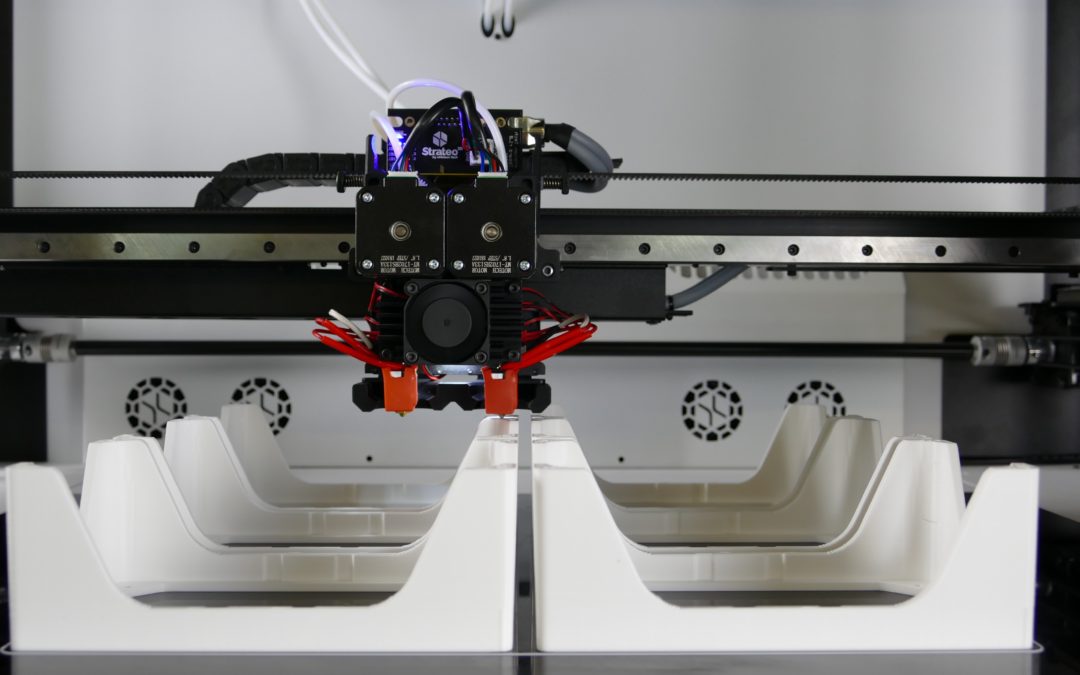

Plastics industry cleanrooms have multiple processes in motion at all times, from traffic of personnel, carts, and cranes, to the operation of large equipment like plastic injection molding machines, which can range in size from 50 to 1,000 tons.

Plastics cleanrooms require consistent cleaning to maintain quality standards and ensure the facility performs at optimal levels. A durable cleanroom is essential to handle day-to-day operations and proper sterilization.

Extremely durable modular panels are made with non-outgassing and non-particle shedding materials, and designed to withstand anything. They’re fire and impact resistant and can handle thorough, regular cleaning protocols without corroding or losing integrity. ESD-safe materials are also available for sensitive applications.

#5 Modular Cleanrooms are Customizable to Your Application

Modular cleanrooms are designed and built off site, but they can still be constructed with full range of customizations. Depending on what you need your cleanroom to do, your cleanroom will support your custom layout, airflow pattern, industry-specific equipment, and cleanroom trades like your HVAC, lighting, and filtration systems.

You can even have your modular cleanroom designed to integrate with systems in your existing structure, so it will fit in any sized space, utilize light from existing windows, connect to your air handling system, and more.

Applications in the plastics industry can use modular cleanrooms to meet requirements set by the ISO and their industry, and set their project up for success by incorporating all the tools and features they’ll need in their modular cleanroom design.

Ready to get started on a modular cleanroom? Give Angstrom Technology a call! We design, build, and install modular cleanrooms to meet any classification requirements. Our prefabricated panels come with detailed instructions, ready to set up right away. Of course, if you’d rather skip the work, have our cleanroom experts install it for you!