Dry Room for Li-Ion Battery Production

Cdp

The Angstrom Group delivered a new dry room for lithium battery production, within a new scale-up facility for Anaphite. Anaphite is a chemistry company developing CNT enhanced cathode powders that can be used to produce dry coated electrodes for low-cost, high-performance Li-ion batteries. To disregard any effects of moisture affecting materials, Anaphite needed an ultra-low dewpoint air supply that could be driven down to minus 75°Cdp, with a target return of at least minus 40°Cdp measured at the point of air return.

- Dry room with combined airlock gowning area

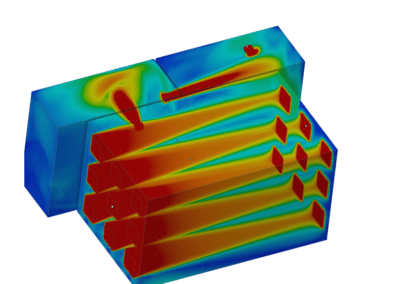

- CFD airflow analysis ensured even distribution of horizontal airflow

- Multi-rotor system to quickly drive the dry room down to specification

- Ultra-low dewpoint air supply that can be driven down to minus 75°Cdp

- Fully sealed panel system combined with fully welded stainless steel providing an ultra-low air leakage rate

- HEPA filtration to deliver ISO 14644-1 Class 7 compliant air within the main area

The main requirement for the dry room was the target dew point and the size, but Anaphite also needed the dry room to be modular. As a start-up, demands, and requirements can soon change, so a modular and relocatable design gives Anaphite the flexibility to adapt to unforeseen changes. The dehumidifier unit, amongst other elements of the project build, is movable, satisfying the need for modularity.