Modular Cleanroom FAQs

Need more details on modular cleanrooms? We’ve got you covered. Below, we’ve answered 10 of the most frequently asked questions we receive about modular cleanrooms here at Angstrom Technology. 1. What Is a Modular Cleanroom? A modular cleanroom is a cleanroom built...

Tips for Cleanroom Cleaning

You’ve spent the money, taken the time, and exhausted the resources needed to design and construct a perfect cleanroom for your facility’s application. It’s fully operational and exceeding your expectations, so now you can just sit back and enjoy the results, right? ...

How Cleanroom Airflow Patterns Are Designed

Every cleanroom is designed to uphold a certain cleanliness level and ISO classification — and a major component of meeting those standards is establishing and maintaining a proper airflow pattern. In fact, ISO 14644-4 designates an entire annex section to discussing...

Understanding the Value of Modular Cleanrooms

At Angstrom Technology, we like to take a step back every once in a while, taking the time to acknowledge and appreciate the impact of our work in various industries. It helps us put our work into perspective, and it motivates us to deliver excellence each and every...

Cleanroom Classification FAQs

Cleanroom classification is often one of the most confusing parts of designing and building a cleanroom. However, it’s also one of the most essential parts, so it’s important that you understand all the relevant information. If you’re installing a cleanroom for the...

Understanding Cleanroom Costs by Type

If your facility needs a controlled space for one or more of its operations, you may be looking into purchasing a cleanroom. However, while doing your research, you may find yourself stuck on which type of cleanroom is the best investment for you: SoftWall, HardWall,...

How to Choose a Fan Filter Unit for your Cleanroom

In order to ensure your facility is meeting required cleanliness standards, fan filter units (FFU) are a critical component of your cleanroom design. Let’s explore more about fan filter units: how they work, what types there are, and how to choose the right one for...

Are Modular Cleanrooms Environmentally Friendly?

Manufacturers and production facilities across the nation are on a continuous search for sustainable solutions. Of course, sustainable solutions help production facilities, labs, and fabrication plants do their part in protecting our environment and natural resources,...

4 Questions to Ask Before Starting Automotive Cleanroom Construction

There’s a lot of planning involved in automotive cleanroom construction. From layout design to operational components, you need to figure out what you need and how to implement it before you start building. Many experienced cleanroom designers and engineers have...

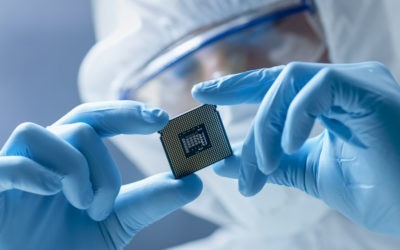

4 Microelectronics Manufacturing Applications that Rely on Cleanrooms

Microelectronics manufacturing often involves delicate materials and occasionally toxic substances that require special care for handling and storage. Manufacturing equipment is also highly sensitive and generates heat which must be controlled. For applications in...